|

Fenghua Hengyi Micro Shaft Co.,Ltd

|

SUS420J2 induction motor shaft chinese manufacturer

| Price: | 0.01~1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Stainless steel, SUS420J2, SUS303,SUS304

2.Standard: ASTM, AISI, BS, DIN, JIS, NF

3.100%QC control

4.ISO9001 TS16949

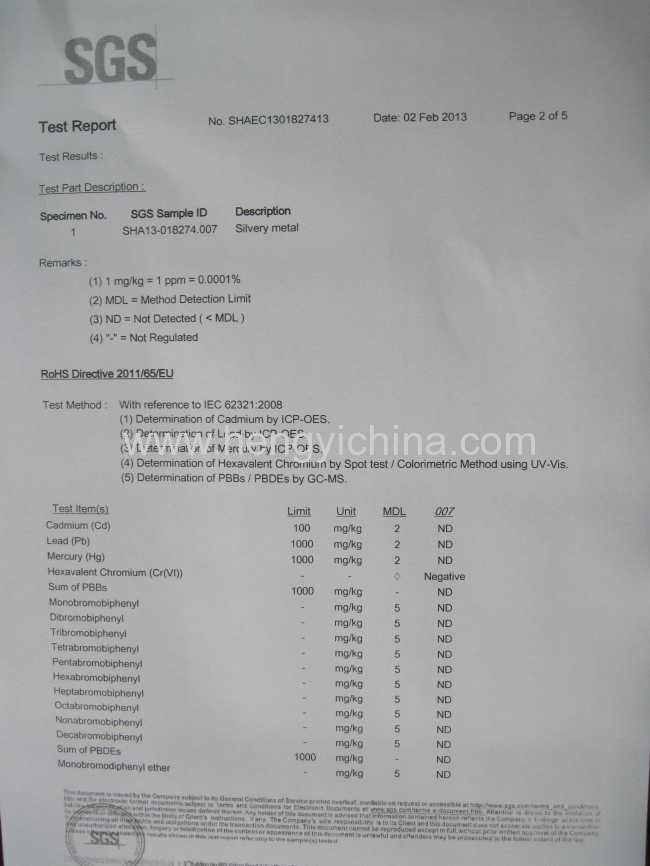

5.RoHS

1. Main introduction

The precision spindles manufactured at Hengyi are between 2mm and 25mm in diameter and 400mm max. in length.

We can provide the followings:

Steel spindles, steel shafts

Stainless steel splindles, stainless steel shafts

Turned spindles Turned shafts

Ground splindles, ground shafts

Gear out splindles, gear our shafts

Heat treated splinles, heat treated shafts

2. Specifications

Material | CK45 | |

O.D.tolerance | 0.001mm | |

Straightness | 0.001mm | |

Roundness | 0.0002mm | |

Cylinderness | 0.0005mm | |

Roughness | Ra.0.001 | |

Runout | 0.01mm | |

Heat treatment | Hardened |

3.Quality System

We work strictly with ISO9001, TS16949 AND 5S methodology

5S is the name of a workplace organization method that uses a list of five Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke. Transliterated or translated into English, they all start with the letter "S". The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work.

We have passedthe second audit of TS16949, We will get the certificate at the end of October'2013

Testing Method

specification | Checking tools |

Symmetry inacross flat | Gauge |

Across flat | DigitalMicrometer/Gauge |

Diameter | DigitalMicrometer |

Rounout | Dial gaugewith" V" block |

Knurling pitchdimension | Digital verniercaliper |

Knurling pitchdiameter | Digitalmicrometer |

Lenth of acrossflat | Digital verniercaliper |

Burnishing areadiameter | DigitalMicrometer/Gauge |

Length | Digital verniercaliper |

Overall lenth | Digital vernier caliper |

Splines diameter | Plain ring gauge |

Hardness | Hardnessrockwell tester |

We have our own testing center,

Runout tester

Roundness tester

Roughness tester

Projector

Hardness tester

Magnifier

4. Process:

We often use ERP system to producing quality control, the processes for the shafts are usally the following:

Raw material(Drawn) → Cutting→Rolling →lather→grinding→polish→final inspection→pick up→package→delivery

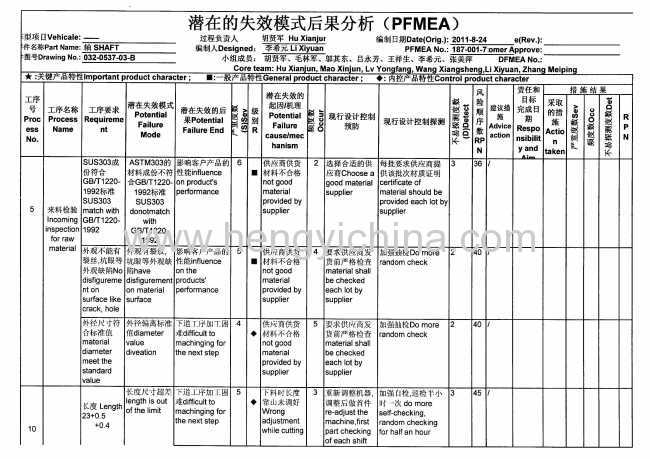

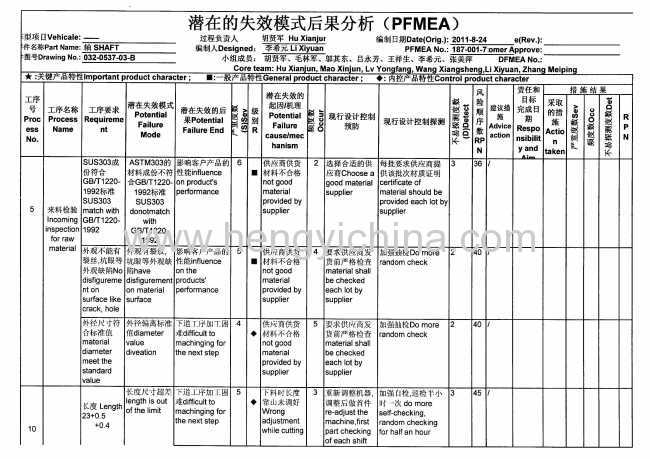

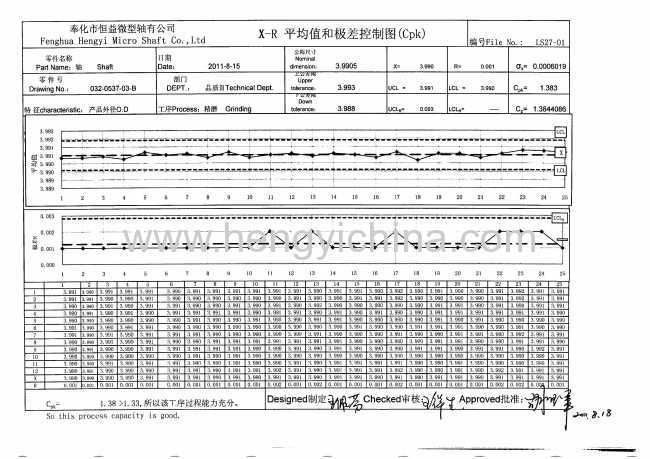

5. PPAP documents

PFEMA

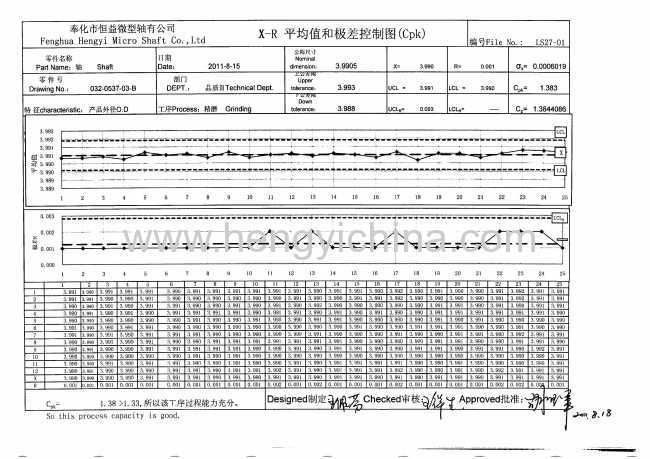

CPK

5. PPAP documents

PFEMA

CPK

Control Plan, process chart.etc

6. Raw material

Raw materials are ROHS tested from the third party every year, such SGS, CTI

7. Production machines

Auto Cutting machines

Heat treatment machins

High precision grinding machines

Auto lathers

M1020 M1050 coreless grinding machines

More than 80 pcs grinding machines

Delivery

FOB NINGBO and CIF are both OK for us

Samples

Samples are avaliable

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Induction Motor

Motor With Shaft

Ac Induction Motor

Induction Electric Motor

Induction Motor Speed

Three Phase Induction Motor

More>>